The group’s circular economy efforts are demonstrated by its efforts to recover as much aluminum as possible and repurpose sodium aluminate, a byproduct that is a significant waste. Its “Plan Progrès” program has been set up to address hazardous and non-hazardous wastes and strives to minimize their environmental impact going forward.

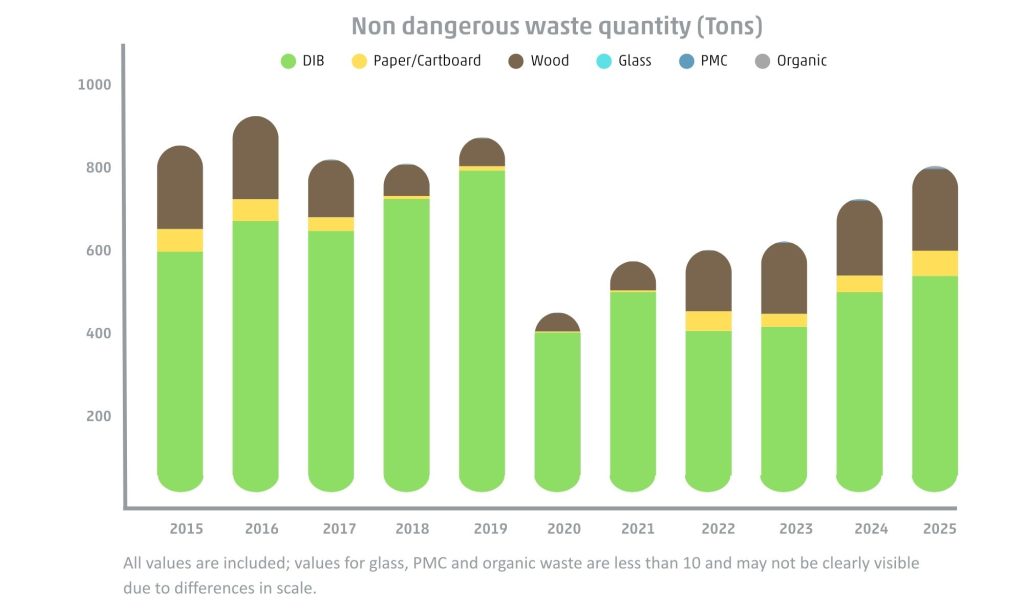

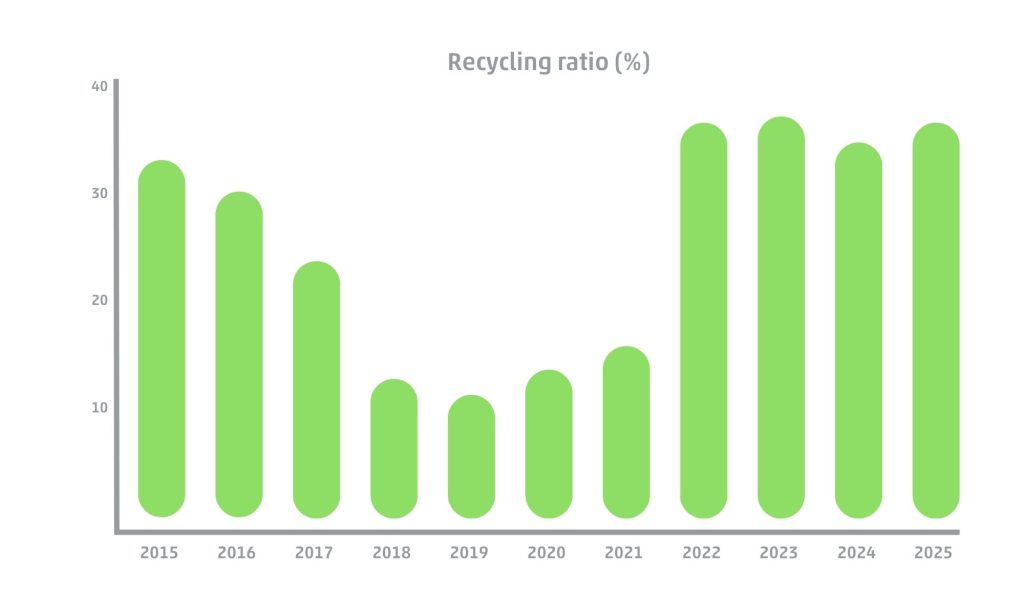

From packaging waste in the canteen and warehouses to the paperless office, the group is attentive on all fronts. Targets have been set to reduce the group’s ordinary industrial waste (OIW) and the data collated is illustrated in the graph below.

Sonaca has developed a repair activity for slats damaged in flight. Repairing these parts significantly reduces the carbon footprint compared to manufacturing new ones, while ensuring a high level of safety thanks to operations performed under the same optimal conditions as the original production process. By 2025, 228 slats had been repaired in this way.