The energy transition is underway. As it too is subject to the vagaries of the social, political, and economic climate, Sonaca has taken tangible actions to reduce consumption and turn towards alternative sources. The solar panels installed in 2020 are a strong example of our commitment to lowering fossil‑fuel use, and a second deployment phase was completed at the end of 2025.

These kinds of decisions bring in their wake a reduction in direct greenhouse gas emissions from owned or controlled processes, as well as indirect emissions from the generation of purchased energy, a pattern that is set to continue thanks to its projected energy consumption and carbon credits.

This green transformation has been achieved through initiatives such as:

- Transitioning the vehicle fleet to electric and more energy‑efficient options

- Reducing material scrap and optimizing production processes

- Implementing energy‑saving measures: automatic standby for equipment, insulated steam pipes, and heat‑recovery systems (paint booth, compressor, etc.)

- Improving logistics efficiency through the use of double‑deck trailers

- Replacing foam extinguishers with PFAS‑free equipment

- Providing training on ethical values

- etc.

A whole array of other repair, replacement, retrofit, recovery, and reduction measures across its plants have been identified, assessed, and applied, involving process owners across Sonaca’s operations and supply chain.

Key figures

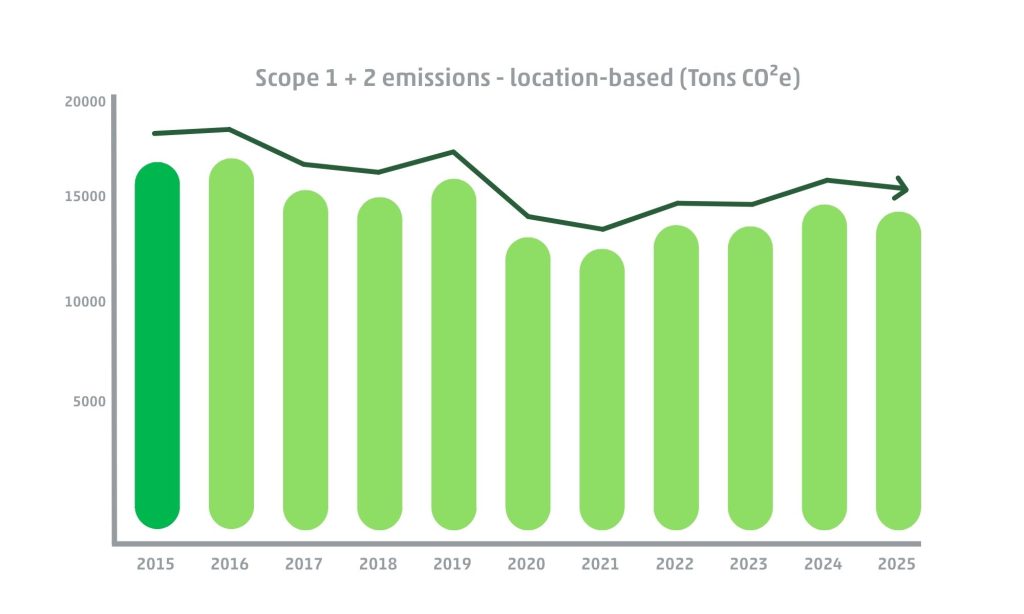

Since 2015, a gradual decrease in greenhouse gas emissions has been observed, driven by structural energy‑saving measures and further amplified by the slowdown in economic activity caused by the COVID-related impact on the aviation sector. Since then, production has returned to pre‑COVID levels, but in 2025 the downward trend in CO₂ emissions will resume, with a 2.6% reduction despite a 6% increase in activity, clearly demonstrating the effectiveness of the actions implemented.

Sonaca has voluntarily joined the Walloon Region’s industrial agreements and committed to reducing its CO₂ emissions by 13% by 2031.

A firm action plan has been defined for several ongoing projects, including compressed air leak reduction, heat recovery, building insulation, and optimization of cooling systems and paint booths, representing an annual reduction of 1,750 tons of CO₂.

An additional conditional action plan is also under review, outlining further measures that could deliver an extra 4,500 ton reduction as an extension of the firm plan.

These plans are further boosted by the use of AI to further enhance energy efficiency.

However, this is not the time for Sonaca to rest on its laurels, as the targets to progress towards an ideal Carbon neutrality by 2050 call for decisive actions and concerted efforts. Sonaca has allocated the necessary resources and recruited a new team member who will work with a data scientist to optimize its operations and further curtail its environmental impact.